Interrobang Automotive

The complete opposite of mass-produced

A small team of designers, tinkerers, and stubborn problem-solvers building modular, durable gear for the Rivian R1T — right here in Akron, Ohio.

Problem → Prototype → Product

We didn’t mean to start a company. We just wanted a better R1T tonneau cover.

Interrobang began as a side project, turned group chat, turned full-scale operation inside an old rubber factory in Akron. We spend our days dreaming up cool new products that you like and working hard to bring those to life.

What do we build? Right now, it’s small-batch truck accessories: modular tonneau covers, low-friction tunnel trays, and experimental gear add-ons; all engineered for the electric truck community. Our small team of designers and innovators are interested in a lot, and are expanding our catalog into other custom designs to serve practical, useful purposes.

Do you have ideas? We want to hear them!

Our Rivian Tonneau Covers

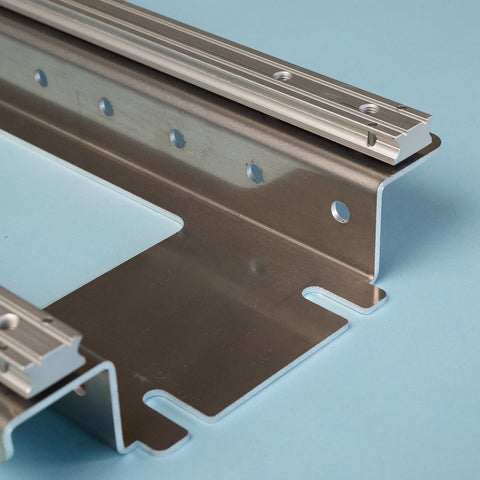

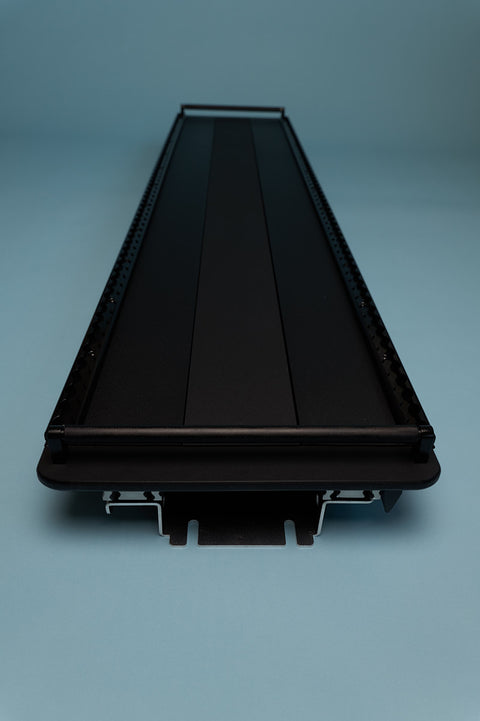

We’ve improved on the original design, but it’s essentially the same now as when we started. Our Rivian tonneau covers are sturdy, easy-to-install, multi-panel powder-coated aluminum covers. Every panel is built and shipped by hand.

Head to our product page to see for yourself: every Interrobang tonneau cover is made to slide right into your Rivian R1T’s existing bedrails. It installs without drilling, folds with ease, and can support serious weight (ask us how we know).

Other Projects We’re Tinkering With

We call them experiments, but they’re really just answers to questions we keep asking. Like:

- What if the gear tunnel actually worked like a drawer?

- Could a tonneau panel become a camp table?

- How much weight is too much weight?

- How much chuck could a wood chuck chuck if a Rivian R1T’s MPGe in the city is 74?

Some ideas stick. Some don’t. But the ones that do go through months of prototyping, testing, re-testing, and occasionally, swearing. That’s how the Tunnel Tray happened. That’s how the V3 straps came to life.

Built in Our Lab in Akron, OH

Okay, it’s not a lab. It’s a 100-year-old factory where they used to make tires, blimps, golf balls, and the first American spacesuit. We rent a corner of it.

Everything we make is designed and built right here. We don’t white-label. We don’t outsource. We test on our own trucks, cut our own panels, and ship straight from the shop floor.

It’s slower, but we do it because it’s better.

Why Interrobang Automotive

We don’t run on VC money, splashy marketing, or “drop culture.” We run on curiosity and community.

We share ideas in forums. We respond to DMs. We give you the info you need to make installation easier. We read the feedback. And when something’s not right, we go fix it. That’s the whole model.

And if you’re the kind of person who wants to mod, experiment, or build it yourself — well, we probably already like you.